Sae 1213 Bright Bars

Sae 1213 Bright Bars Specification

- Hardness

- 140-165 HB

- Purity

- 99.9%

- Strength

- Tensile Strength 440 MPa (min)

- Product Type

- Bright Bar

- Material

- Steel

- Alloy

- Low Carbon Steel (Sae 1213)

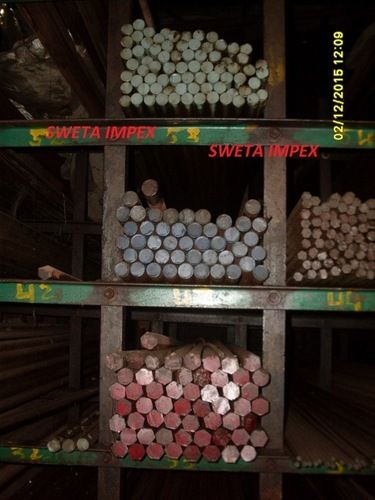

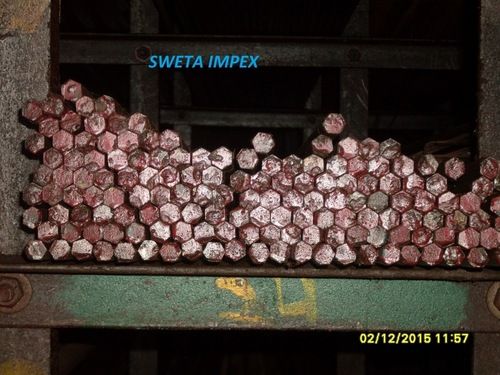

- Shape

- Round, Square, Hexagonal

- Moisture

- Nil

- Chemical Composition

- C: 0.13%, Mn: 0.85%, P: 0.040%, S: 0.045%

- Application

- Automobile, Engineering, Machinery

- Dimension (L*W*H)

- Standard: Diameter 8 mm to 60 mm, Length up to 6000 mm

- Color

- Bright Silver

- Density

- 7.85 g/cm³

- Heat Treatment

- Annealed or Unannealed

- Standards

- ASTM A108, IS 9550

- Stock Availability

- Ready Stock

- Surface Finish

- Mirror Bright

- Yield Strength

- 350 MPa

- Magnetic Property

- Magnetic

- Packing

- Bundle Packing or Box Packing

- Elongation

- 16% (Min)

- Corrosion Resistance

- Moderate

- Tolerance

- H9/H11 as per requirement

Sae 1213 Bright Bars Trade Information

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, North America, Australia

- Main Domestic Market

- All India

About Sae 1213 Bright Bars

Sae 1213 Bright Bars

We will Give YOU Sae 1213 Bright Bars of Good Quality. The Sae 1213 Bright Bars manufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

we will Supply Sae 1213 Bright Bars as per your required size and quantity.

The BEST & lowest rate for Sae 1213 Bright Bars will be given to You

Buy Sae 1213 Bright Bars from us.

we can SEE Long term HEALTHY relationship with YOU

Please mail us Your requirement so that we can Give You our Best & Lowest quote for Sae 1213 Bright Bars

YES . Bright Bar Manufacturer

Bright Bar Supplier

- Trusted Steel Suppliers In Mumbai

- Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters

- We Will Give Excise Cen Vat Credit EN 15 Bright Bars Bright Bar Manufacturer in India Manufacturer Of Bright Bars flat bright bars

Quality Material Supplier

Genuine Steel Supplier In India

We Export Bright Bars

We Give Export Quality Bright Bars

Chemical Composition of Alloy Steel

Export Quality Bright Steel Bars

Export Quality Machined Components

Exporters Of Steel Bright Rods

S S 304 Flat Manufacturers and Exporters

Cold Drawn Steel Exporter

Cold Drawn Bright Steel Manufacturers And Exporters

Peeled Bright Round

Manufacturers And ExportersEn1A 28mm Bright Bars Manufacturers and Exporters

Cold Drawn Stainless Steel Manufacturers and Exporters

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En1A 28mm non Leaded Bright Bars Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Steel Rods Manufacturers and Exporters

Sae 1040 Cold Drawn Bright Bars Manufacturers and Exporters En 8 Bright Bars

Carbon Steel Bright Bars EN1a Bright Bars Sae 1045 Bright Bars Manufacturers Exporters

Carbon Steel Bright bars Manufacturers & Exporters Sae 1040 Steel Bright Bars Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Round Manufacturers and Exporters

Sae 1541 Steel Cold Drawn Bright Round Manufacturers and Exporters

Mirror Bright Finish for Enhanced Appearance

SAE 1213 Bright Bars offer a mirror-bright surface, achieved through advanced processing. This finish not only improves aesthetic appeal but also serves functional benefits by reducing surface imperfections and facilitating smoother assembly in various industries, such as automotive and machinery.

High Mechanical Strength and Durability

With a yield strength of 350 MPa and tensile strength above 440 MPa, these bars provide exceptional load-bearing capabilities. Their 16% minimum elongation ensures flexibility while maintaining structural integrity, making them suitable for demanding engineering applications.

Versatile Dimensions and Stock Readiness

Available in diameters from 8 mm to 60 mm and lengths up to 6000 mm, SAE 1213 Bright Bars cater to diverse project requirements. Shapes include round, square, and hexagonal, supplied in ready stock for quick, reliable delivery to customers globally.

FAQs of Sae 1213 Bright Bars:

Q: How are SAE 1213 Bright Bars typically used in manufacturing and engineering?

A: SAE 1213 Bright Bars are favored in manufacturing and engineering for producing components that require precise tolerances, high strength, and excellent surface finish. They are commonly utilized in automotive, machinery, and engineering sectors for shafts, fasteners, and structural parts.Q: What benefits does the mirror-bright surface finish provide to end-users?

A: The mirror-bright surface finish enhances the visual appeal and minimizes surface defects. This finish also facilitates easier cleaning, reduces friction in moving parts, and helps with efficient assembly of high-precision components.Q: When should you opt for annealed versus unannealed SAE 1213 Bright Bars?

A: Annealed bright bars are preferred when additional ductility and machinability are required, especially in forming or bending processes. Unannealed bars retain higher hardness and strength, making them ideal for applications needing greater wear resistance.Q: Where can I source SAE 1213 Bright Bars and what packing options are available?

A: SAE 1213 Bright Bars are readily available through manufacturers, dealers, exporters, importers, and retailers. Packing options include bundle packing for bulk shipments or box packing for enhanced protection during transport.Q: What is the manufacturing process for SAE 1213 Bright Bars?

A: These bars are typically formed by cold drawing or rolling low carbon steel material, followed by precision machining to achieve exact tolerances and then polished to create a mirror-bright surface finish. Heat treatment such as annealing may also be performed as required.Q: How does the moderate corrosion resistance affect usage in various environments?

A: Moderate corrosion resistance means these bars perform well in standard indoor environments but may require additional protective measures such as coating or plating when used in highly corrosive or outdoor conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN1A Steel Category

EN1A Leaded Bright B

Purity : 99% pure metal constituents (approx.)

Chemical Composition : C: 0.15% max, Mn: 0.80% max, S: 0.25% 0.35%, Pb: 0.15% 0.35%

Strength : 400550 MPa (Tensile)

Color : Bright Silver

Material : EN1A Leaded Mild Steel

Alloy : Free Cutting Steel (EN1A Leaded)

28mm EN1A Cold Bright bars

Purity : 99% (Approx)

Chemical Composition : Carbon: 0.15% max, Manganese: 0.801.00%, Sulphur: 0.270.35%, Phosphorus: 0.07% max

Strength : Tensile Strength 370470 MPa

Color : Silver Grey

Material : EN1A

Alloy : Low Carbon Free Cutting Steel

Sae 12L14 Bright Bar

Purity : 99% min.

Chemical Composition : C: 0.15% max, Mn: 0.85% max, P: 0.04% max, S: 0.270.33%, Pb: 0.150.35%, Fe: Balance

Strength : Tensile Strength: 415550 MPa

Color : Bright Silver White

Material : Steel

Alloy : 12L14 Free Cutting Steel

EN1A Bright Bars

Purity : High purity with minimal impurities

Chemical Composition : Carbon (C): 0.09% 0.13%

Strength : Moderate tensile strength

Color : Silver, Bright

Material : EN1A

Alloy : NonAlloy

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS