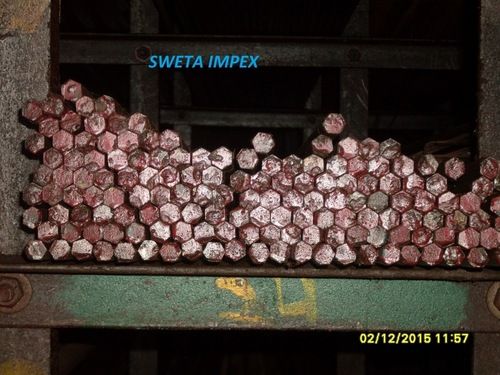

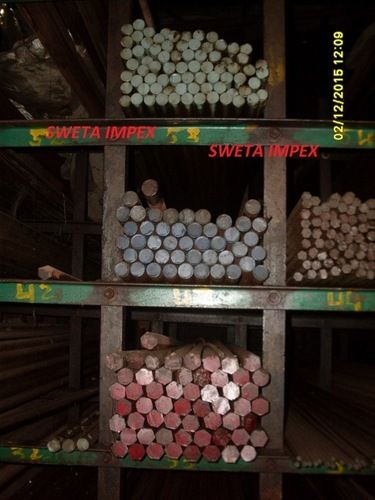

EN1A Bright Bars

Price 90 INR/ Kilograms

EN1A Bright Bars Specification

- Strength

- Moderate tensile strength

- Purity

- High purity with minimal impurities

- Material

- EN1A

- Alloy

- Non-Alloy

- Moisture

- Low moisture content

- Chemical Composition

- Carbon (C): 0.09% 0.13%

- Color

- Silver, Bright

EN1A Bright Bars Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, North America, Australia

- Main Domestic Market

- All India

About EN1A Bright Bars

EN1A Bright Bars

- We will Give YOU EN1A Bright Barsof Good Quality. The EN1A Bright Barsmanufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

- we will Supply EN1A Bright Barsas per your required size and quantity.

- The BEST & lowest rate for EN1A Bright Barswill be given to You

- Buy EN1A Bright Barsfrom us.

- we can SEE Long term HEALTHY relationship with YOU

- Please mail us Your requirement so that we can Give You our Best & Lowest quote for EN1A Bright Bars

- YES . Bright Bar Manufacturer

Bright BarSupplier

- Trusted Steel Suppliers In Mumbai

- Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel

- We Will Give Excise Cen Vat CreditEN 15 Bright Bars Bright Bar Manufacturer in IndiaManufacturer OfBright Bars flat bright bars

Quality Material Supplier

Genuine Steel Supplier In India

We Export Bright Bars

We Give Export Quality Bright Bars

Chemical Composition of Alloy Steel

Export Quality Bright Steel Bars

Export Quality Machined Components

Exporters Of Steel Bright Rods

S S 304 Flat Manufacturers and Exporters Cold Drawn Steel Exporter S S 316 Stainless Steel Cold Drawn Bright Rods

Manufacturers And Exporters

Cold Drawn Stainless Steel Manufacturers and Exportersrs

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel ColdDrawn BrightSteelRodsManufacturers and Exporters

Sae 1040ColdDrawn BrightBarsManufacturers and Exporters

BestQualityEn 8BrightSteelRodsManufacturers and Exporters

En 8BrightSteel Cold DrawnRoundAndHexagonRodsManufacturers and Exporters

BestQualityFree CuttingSteel ColdDrawn BrightRodsManufacturers and Exporters

En 8Steel Cold Drawn BrightBarsManufacturers and Exporters

BestQualityFree CuttingSteel ColdDrawn BrightRodsManufacturers and Exporters

Free Cutting Steel En 8Carbon SteelManufacturers and ExportersCarbon SteelFree Cutting Steel

En 8BrightBarsCarbon SteelBrightBarsEN1aBrightBarsEn 8BrightBarsManufactures Exporters

Sae 1045BrightBarsManufacturers ExportersCarbon SteelBright barsManufacturers & Exporters

Sae 1040 SteelBrightBarsManufacturers and Exporters

Carbon Steel ColdDrawn BrightRoundManufacturers and Exporters

Sae 1541Steel ColdDrawn BrightRoundManufacturers and Exporters

Free CuttingSteel ColdDrawn BrightBarsManufacturers and Exporters

Superior Quality and Surface Finish

EN1A Bright Bars are meticulously manufactured to deliver an exceptional bright surface and consistent finish. The tight diameter tolerance of 0.05mm ensures precise dimensions, while the high purity guarantees minimal impurities. Their impressive ductility and moderate tensile strength make them well-suited for demanding machining environments where accuracy and performance matter most.

Versatile Applications Across Industries

These bright bars serve a broad range of industries, including automotive, engineering, construction, and machinery manufacturing. Their adaptability stems from high machinability, excellent wear resistance, and reliable corrosion protection. Whether for precision components, shafts, or fasteners, EN1A Bright Bars offer long-lasting performance and cost efficiencies for users throughout India.

FAQs of EN1A Bright Bars:

Q: How are EN1A Bright Bars manufactured to maintain a high-quality surface finish?

A: EN1A Bright Bars are produced using advanced drawing and polishing processes, followed by strict quality control to ensure a bright, smooth surface and accurate diameter tolerance. This method removes surface imperfections and achieves the signature silver, bright finish.Q: What makes EN1A Bright Bars suitable for machining and precision engineering uses?

A: These bars offer excellent machinability due to their specific chemical composition and high purity. The consistent dimensions and moderate tensile strength make them ideal for applications requiring intricate machining and precision fitting, such as gears, fasteners, and shafts.Q: Where can I use EN1A Bright Bars in industrial or manufacturing settings?

A: EN1A Bright Bars can be utilized in automotive components, machinery parts, construction frameworks, and general engineering projects. Their versatility extends to any field where high strength, wear resistance, and good ductility are necessary.Q: What benefits do EN1A Bright Bars provide compared to other steel bars?

A: EN1A Bright Bars offer several advantages: enhanced machinability for easy shaping, corrosion resistance for longevity, high strength for structural integrity, and cost-effectiveness for economical manufacturing. Their low moisture content and minimal impurities further ensure product reliability.Q: When should I choose EN1A Bright Bars over alternative materials?

A: EN1A Bright Bars are preferred when projects demand moderate tensile strength, high machinability, and precise dimensions while maintaining a cost-effective solution. They are particularly advantageous in high-volume production environments and for components that require fine tolerances.Q: What processes are involved in customizing EN1A Bright Bars to specific requirements?

A: Customization typically includes specific cutting, shaping, and finishing according to client drawings. The bars are available in round or hexagonal shapes and can be cut to desired lengths, ensuring they match the applications needs exactly.Q: How does the non-alloy composition benefit the properties of EN1A Bright Bars?

A: The non-alloy nature of EN1A Bright Bars results in consistent mechanical properties and improved machinability. It also means fewer variables during processing, making these bars a dependable choice for manufacturers seeking uniform performance in production batches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN1A Steel Category

EN1A Leaded Bright B

Material : EN1A Leaded Mild Steel

Application : Other, Machining, precision components, fasteners, automotive parts

Chemical Composition : C: 0.15% max, Mn: 0.80% max, S: 0.25% 0.35%, Pb: 0.15% 0.35%

Purity : 99% pure metal constituents (approx.)

Color : Bright Silver

Alloy : Free Cutting Steel (EN1A Leaded)

Sae 12L14 Bright Bar

Material : Steel

Application : Other, Automobile Components, Shafts, Fasteners, Precision Parts, Engineering Applications

Chemical Composition : C: 0.15% max, Mn: 0.85% max, P: 0.04% max, S: 0.270.33%, Pb: 0.150.35%, Fe: Balance

Purity : 99% min.

Color : Bright Silver White

Alloy : 12L14 Free Cutting Steel

Sae 1213 Bright Bars

Material : Steel

Application : Other, Automobile, Engineering, Machinery

Chemical Composition : C: 0.13%, Mn: 0.85%, P: 0.040%, S: 0.045%

Purity : 99.9%

Color : Bright Silver

Alloy : Low Carbon Steel (Sae 1213)

28mm EN1A Cold Bright bars

Material : EN1A

Application : Other, Machining, Auto Parts, Fasteners, Engineering Components

Chemical Composition : Carbon: 0.15% max, Manganese: 0.801.00%, Sulphur: 0.270.35%, Phosphorus: 0.07% max

Purity : 99% (Approx)

Color : Silver Grey

Alloy : Low Carbon Free Cutting Steel

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free