EN 24 Bright Bars

EN 24 Bright Bars Specification

- Strength

- Tensile Strength: 850-1000 MPa (varies as per heat treatment)

- Purity

- 99% (Typical for alloy steel grade)

- Hardness

- 248-302 HB (Annealed Condition)

- Product Type

- Bright Bar

- Material

- Alloy Steel, EN 24 grade

- Alloy

- EN24 (Alloy Steel)

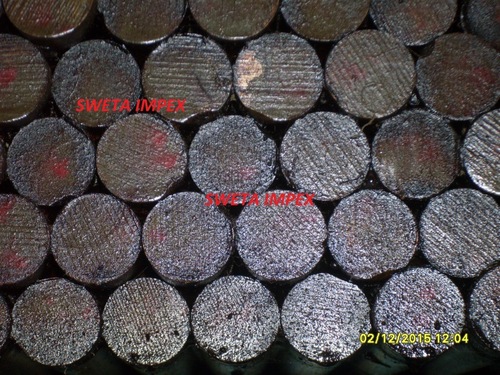

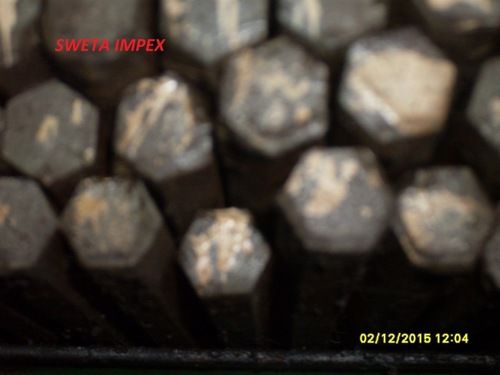

- Shape

- Round, Square, Hexagonal

- Moisture

- Nil (Metal product, moisture-free)

- Chemical Composition

- C: 0.36-0.44%, Mn: 0.45-0.70%, Si: 0.10-0.35%, Cr: 0.90-1.40%, Mo: 0.20-0.35%, Ni: 1.30-1.80%, S: 0.040% Max, P: 0.035% Max

- Application

- Automotive components, Shafts, Gears, Bolts, Engineering, Heavy-duty machinery

- Dimension (L*W*H)

- Custom Length x Diameter (Round) or Custom Size (Square/Hex)

- Color

- Bright Silver/Grey

- Form

- Cold Drawn or Peeled & Ground

- Finish Type

- Bright, Polished

- Standards

- EN24 (BS 817M40), AISI 4340 equivalent

- Density

- 7.85 g/cm³

- Machinability

- Good

- Delivery Condition

- Annealed/Normalized/Quenched and Tempered as required

- Surface Condition

- Free from scale and decarburization

- Tolerance

- h9, h11 (Standard Engineering Tolerances)

- Section Size Range

- Diameter 10 mm to 100 mm (customization possible)

- Corrosion Resistance

- Moderate (may require protective coatings for severe environments)

EN 24 Bright Bars Trade Information

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About EN 24 Bright Bars

EN 24 Bright Bars

We will Give YOU EN 24 Bright Bars of Good Quality. The EN 24 Bright Bars manufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

we will Supply EN 24 Bright Bars as per your required size and quantity.

The BEST & lowest rate for EN-8 Bright Bars will be given to You

Buy EN 24 Bright Bars from us.

we can SEE Long term HEALTHY relationship with YOU

Please mail us Your requirement so that we can Give You our Best & Lowest quote for EN 24 Bright Bars

YES Bright Bar Manufacturer

Bright Bar Supplier

Trusted Steel Suppliers In Mumbai

Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel

We Will Give Excise Cen Vat Credit EN 15 Bright Bars Bright Bar Manufacturer in India Manufacturer Of Bright Bars flat bright bars

Quality Material Supplier

Genuine Steel Supplier In India

We Export Bright Bars

We Give Export Quality Bright Bars

Chemical Composition of Alloy Steel

Export Quality Bright Steel Bars

Export Quality Machined Components

Exporters Of Steel Bright Rods

S S 304 Flat Manufacturers and Exporters

Cold Drawn Steel Exporter

Cold Drawn Bright Steel Manufacturers And Exporters

Peeled Bright Round

Manufacturers And Exporters

S S 316 Stainless Steel Cold Drawn Bright Rods

Manufacturers And ExportersCold Drawn Stainless Steel Manufacturers and Exporters

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Steel Rods Manufacturers and Exporters

Sae 1040 Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality En 8 Bright Steel Rods Manufacturers and Exporters

En 8 Bright Steel Cold Drawn Round And Hexagon Rods Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters

Free Cutting Steel En 8 Carbon Steel Manufacturers and Exporters Carbon Steel Free Cutting Steel

En 8 Bright Bars Carbon Steel Bright Bars EN1a Bright Bars En 8 Bright Bars Manufactures Exporters

Sae 1045 Bright Bars Manufacturers Exporters Carbon Steel Bright bars Manufacturers & Exporters

Sae 1040 Steel Bright Bars Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Round Manufacturers and Exporters

Sae 1541 Steel Cold Drawn Bright Round Manufacturers and Exporters

Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters

Superior Alloy Composition

Manufactured with a precise blend of carbon, manganese, silicon, chromium, molybdenum, and nickel, EN 24 Bright Bars provide a robust balance of strength, toughness, and machinability. This alloy composition ensures reliability and durability in demanding engineering applications.

Versatile Delivery Conditions

EN 24 Bright Bars can be supplied in various delivery conditions, including annealed, normalized, or quenched and tempered, to suit different mechanical requirements. This flexibility provides engineers and manufacturers with optimal choices for their specific project needs.

Precision and Finish Quality

Finished to h9 or h11 standard engineering tolerances, each bar undergoes cold drawing or is peeled & ground to achieve bright, polished surfaces free from scale and decarburization. This ensures both dimensional accuracy and an excellent surface condition for superior performance and visual appeal.

FAQs of EN 24 Bright Bars:

Q: How are EN 24 Bright Bars typically used in industry applications?

A: EN 24 Bright Bars are commonly utilized in automotive components, shafts, gears, bolts, and heavy-duty machinery owing to their high strength, good machinability, and robust wear resistance, making them suitable for demanding engineering applications.Q: What is the manufacturing process for EN 24 Bright Bars?

A: These bars are produced through cold drawing or by being peeled and ground after initial hot rolling. They are then delivered in annealed, normalized, or quenched and tempered conditions, ensuring precise mechanical properties and a bright, polished finish.Q: When should I choose EN 24 Bright Bars with particular tolerances like h9 or h11?

A: Selecting h9 or h11 tolerances depends on the degree of precision required for your application. h9 offers tighter dimensional accuracy, suited for components needing critical fit, while h11 allows for standard engineering tolerances in less demanding parts.Q: Where can EN 24 Bright Bars be sourced?

A: EN 24 Bright Bars are available through multiple channels, including dealers, manufacturers, suppliers, exporters, importers, retailers, traders, and wholesalers. Many suppliers offer customization options for size and delivery conditions.Q: What are the benefits of using EN 24 Bright Bars with a bright, polished finish?

A: A bright, polished finish enhances the bars appearance, improves corrosion resistance (especially when paired with protective coatings), and ensures a surface free from scale and decarburization, crucial for critical engineering components.Q: How does the moderate corrosion resistance of EN 24 Bright Bars affect their usage?

A: While EN 24 Bright Bars have moderate corrosion resistance, they are best used in environments with minimal exposure to severe corrosive conditions. For harsher environments, applying protective coatings or using additional treatments is recommended to extend service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sae 4340 Bright.Bars Category

Sae 4340 Bright Bars

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Alloy : Alloy Steel (Nickel, Chromium, Molybdenum)

Material : SAE 4340 (NickelChromiumMolybdenum Alloy Steel)

Moisture : Low moisture content

Chemical Composition : Carbon (C): 0.38% 0.43%

Sae 4340 Bright Bars

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Alloy : NickelChromiumMolybdenum Alloy Steel

Material : SAE 4340 Alloy Steel

Moisture : Moistureresistant

Chemical Composition : Carbon (0.380.43%)

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free