Bright Bar Suppliers

Bright Bar Suppliers Specification

- Material

- Mild Steel

- Texture Type

- Bright

- Quality Level

- Premium Grade

- Coating

- Uncoated / As per requirement

- Length

- 3 m, 6 m, or Customized

- Diameter

- 6 mm to 100 mm

- Hardness

- 150-210 HB (Brinell)

- Precision

- High Dimensional Accuracy

- Roundness

- Highly Precise Roundness

- Thickness

- 6 mm to 100 mm

- Tensile Strength

- Up to 600 MPa

- Surface Finish

- Smooth and Bright Surface Finish

- Packaging Type

- Bundle or as per client specifications

- Delivery Condition

- Cold Drawn / Peeled / Polished / Ground / Turned

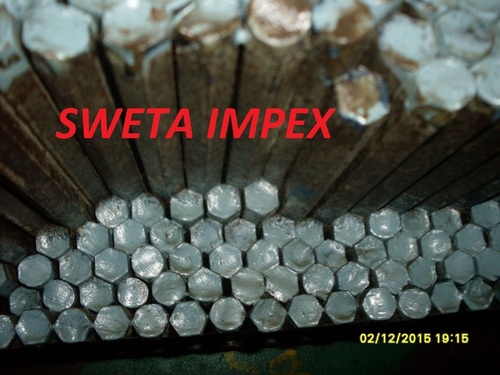

- Shape

- Round, Square, Hexagonal, Flat, and Rectangular

- Weight

- Dependent on Size & Length

- Standard

- ASTM, IS, DIN, EN (as per requirement)

- Edge Condition

- Sharp and True Edges for Flats and Squares

- Application

- Automotive, Construction, Engineering, Machinery

- Product Type

- Bright Bar

- Corrosion Resistance

- Available with Surface Protective Finish

Bright Bar Suppliers Trade Information

- Minimum Order Quantity

- 500 Kilograms

- FOB Port

- x-works

- Payment Terms

- Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Kilograms Tons Per Month

- Delivery Time

- Immediate Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Well Packed, Fully Protected.

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Central America, Asia, Africa

- Main Domestic Market

- All India

About Bright Bar Suppliers

Bright Bar SuppliersWe will Give YOU Bright Bar Suppliers of Good Quality. The Bright Bar Suppliers manufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

we will Supply Bright Bar Suppliers as per your required size and quantity.

The BEST & lowest rate for Bright Bar Suppliers will be given to You

Buy Bright Bar Suppliers from us.

we can SEE Long term HEALTHY relationship with YOU

Please mail us Your requirement so that we can Give You our Best & Lowest quote for Bright Bar Suppliers

YES . Bright Bar Manufacturer

Bright Bar Supplier

- Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel

- We Will Give Excise Cen Vat Credit EN 15 Bright Bars Bright Bar Manufacturer in India Manufacturer Of Bright Bars Trusted Steel Suppliers In Mumbai flat bright bars

- Quality Material Supplier

- Genuine Steel Supplier In India

- We Export Bright Bars

- We Give Export Quality Bright Bars Chemical Composition of Alloy Steel

Export Quality Bright Steel Bars

Exporters Of Steel Bright Rods

S S 304 Flat Manufacturers and Exporters Cold Drawn Steel Exporter Cold Drawn Bright Steel Manufacturers And Exporters Peeled Bright Round

Manufacturers And Exporters

S S 316 Stainless Steel Cold Drawn Bright Rods

Manufacturers And Exporters

Cold Drawn Stainless Steel Manufacturers and Exporters

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Steel Rods Manufacturers and Exporters

Sae 1040 Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality En 8 Bright Steel Rods Manufacturers and Exporters

En 8 Bright Steel Cold Drawn Round And Hexagon Rods Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters Bright Bars

Free Cutting Steel En 8 Carbon Steel Manufacturers and Exporters Carbon Steel Free Cutting Steel

Carbon Steel Bright Bars EN1a Bright Bars En 8 Bright Bars Manufactures Exporters

Sae 1045 Bright Bars Manufacturers Exporters

Carbon Steel Cold Drawn Bright Round Manufacturers and Exporters

Sae 1541 Steel Cold Drawn Bright Round Manufacturers and Exporters

Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters

Exceptional Surface Quality and Strength

Our Bright Bars feature a smooth and bright surface finish, crafted through advanced cold drawing, peeling, polishing, or grinding processes. This meticulous production ensures not only a visually appealing texture but also enhances the strength and corrosion resistance of the bars, making them reliable for critical applications.

Versatile Applications Across Multiple Sectors

Engineered to meet demanding standards such as ASTM, IS, DIN, and EN, our bright bars are suitable for use in automotive components, construction frameworks, engineering applications, and heavy industrial machinery. The bars maintain consistent quality due to strict adherence to global standards and premium-grade mild steel materials.

Flexible Sizing and Customization Options

Bright Bars are available in an extensive range of diameters (6 mm to 100 mm), thicknesses, and lengths (standard 3 m, 6 m, or customized). This flexibility ensures that buyers can select the perfect product to suit their specific needs, from small-scale engineering works to large industrial structures.

FAQs of Bright Bar Suppliers:

Q: How are Bright Bars manufactured to achieve high dimensional accuracy and smooth surface finish?

A: Bright Bars are produced using precise cold drawing, peeling, polishing, grinding, or turning processes. These methods ensure sharp and true edges for flats and squares, and provide highly precise roundness, resulting in a smooth and bright surface finish suitable for engineering and industrial applications.Q: What applications are Bright Bars commonly used for in India?

A: Bright Bars are widely used in automotive manufacturing, construction frameworks, engineering structures, and machinery production. Their corrosion-resistant surface finish and high tensile strength make them essential for critical components that demand reliability and durability.Q: When should corrosion-resistant Bright Bars with surface protective coating be chosen?

A: Corrosion-resistant Bright Bars with a surface protective finish are recommended for environments exposed to moisture, chemicals, or outdoor elements. This added finish helps to prolong the lifespan of bars in construction, engineering, or machinery installations where protection against rust is crucial.Q: Where can customized sizes of Bright Bars be sourced, and what options are available?

A: Customized sizes of Bright Bars are readily available from suppliers across India, including major dealers, wholesalers, manufacturers, and exporters. Clients can specify requirements for thickness (6 mm to 100 mm), length (3 m, 6 m, or custom), and coating or surface finish as per their project demands.Q: What are the benefits of using premium-grade Bright Bars over standard steel bars?

A: Premium-grade Bright Bars offer superior dimensional accuracy, enhanced mechanical strength (up to 600 MPa), higher precision in roundness, and a smooth, bright finish. These advantages translate into improved performance, longer service life, and reduced maintenance in automotive, engineering, and industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bright Bar Category

Bright Bar Manufacturers

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Bright Bars

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS