Sae 12L14 Bright Bar

Sae 12L14 Bright Bar Specification

- Hardness

- Rockwell B 70 - 85

- Strength

- Tensile Strength: 415-550 MPa

- Purity

- 99% min.

- Product Type

- Bright Bar

- Material

- Steel

- Alloy

- 12L14 Free Cutting Steel

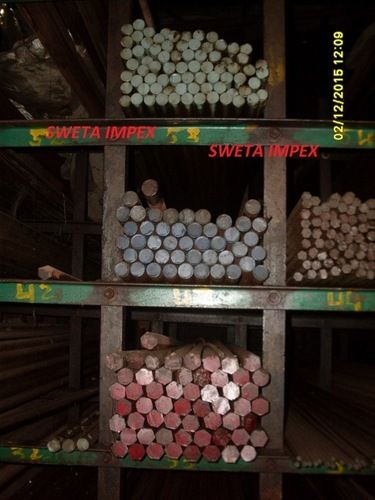

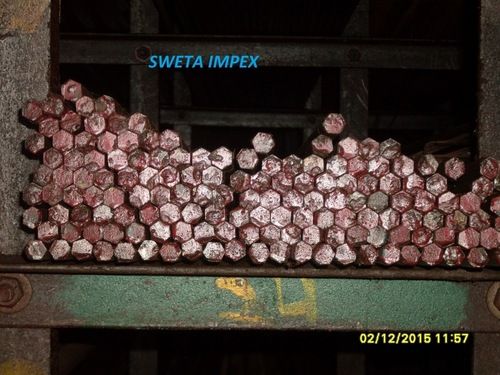

- Shape

- Round / Hexagonal / Square

- Moisture

- Nil

- Chemical Composition

- C: 0.15% max, Mn: 0.85% max, P: 0.04% max, S: 0.27-0.33%, Pb: 0.15-0.35%, Fe: Balance

- Application

- Automobile Components, Shafts, Fasteners, Precision Parts, Engineering Applications

- Dimension (L*W*H)

- As per requirement (standard sizes available: Diameter 5mm-100mm, Length up to 6000mm)

- Color

- Bright Silver White

- Corrosion Resistance

- Moderate

- Density

- 7.87 g/cm³

- Tolerance

- h9, h11 or as specified

- Surface Finish

- Bright Drawn, Polished

- Standard

- ASTM, SAE J403, IS 1875

- Packaging

- Bundled with steel strips or as per client requirement

- Elongation

- 15-20% in 50mm gauge length

- Machinability

- High (Free Cutting)

- Delivery Condition

- Cold Drawn / Peeled / Turned and Polished

Sae 12L14 Bright Bar Trade Information

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Sae 12L14 Bright Bar

Sae 12L14 Bright Bars- We will Give YOU Sae 12L14 Bright Bars of Good Quality. The Sae 12L14 Bright Bars manufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

- we will Supply Sae 12L14 Bright Bars as per your required size and quantity.

- The BEST & lowest rate for Sae 12L14 Bright Bars will be given to You

- Buy Sae 12L14 Bright Bars from us.

- we can SEE Long term HEALTHY relationship with YOU

- Please mail us Your requirement so that we can Give You our Best & Lowest quote for Sae 12L14 Bright Bars

- YES. Bright Bar Manufacturer

Bright Bar Supplier

- Trusted Steel Suppliers In Mumbai

- Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel

- We Will Give Excise Cen Vat Credit EN 15 Bright Bars Bright Bar Manufacturer in India Manufacturer Of Bright Bars flat bright bars

- Quality Material Supplier

- Genuine Steel Supplier In India

- We Export Bright Bars Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters

- We Give Export Quality Bright Bars

Chemical Composition of Alloy Steel

Export Quality Bright Steel Bars

Export Quality Machined Components

Exporters Of Steel Bright Rods

S S 304 Flat Manufacturers and Exporters

Cold Drawn Steel Exporter

Cold Drawn Bright Steel Manufacturers And Exporters

Peeled Bright Round

Manufacturers And Exporters

S S 316 Stainless Steel Cold Drawn Bright Rods

Manufacturers And ExportersCold Drawn Stainless Steel Manufacturers and Exporters

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Steel Rods Manufacturers and Exporters

Sae 1040 Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality En 8 Bright Steel Rods Manufacturers and Exporters

En 8 Bright Steel Cold Drawn Round And Hexagon Rods Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters Bright Bars

Free Cutting Steel En 8 Carbon Steel Manufacturers and Exporters Carbon Steel Free Cutting Steel

En 8 Bright Bars Carbon Steel Bright Bars EN1a Bright Bars En 8 Bright Bars Manufactures Exporters

Sae 1045 Bright Bars Manufacturers Exporters Carbon Steel Bright bars Manufacturers & Exporters

Carbon Steel Cold Drawn Bright Round Manufacturers and Exporters

Sae 1541 Steel Cold Drawn Bright Round Manufacturers and Exporters

Exceptional Machinability for Precision Work

SAE 12L14 Bright Bar stands out for its superior machinability, attributed to its free-cutting alloy composition. This characteristic makes it a preferred choice for manufacturers seeking efficiency and quality in producing precision parts for automotive or engineering industries. The presence of lead further enhances chip formation, enabling higher speeds and extended tool life.

Versatile Dimensions and Surface Finishes

Available in a variety of shapesround, hexagonal, and squarethe SAE 12L14 Bright Bar can be tailored to suit specific project requirements. Customers can choose from standard diameters (5mm to 100mm) and lengths up to 6000mm, with tolerance options of h9, h11, or customized as needed. Multiple surface finishes, such as bright drawn or polished, ensure both performance and aesthetics.

FAQs of Sae 12L14 Bright Bar:

Q: How is the SAE 12L14 Bright Bar delivered and packaged?

A: These bright bars are delivered in cold drawn, peeled, turned, and polished conditions to guarantee surface quality and dimensional accuracy. For secure transportation, each bar is typically bundled with steel strips or packaged according to the clients specifications.Q: What are the main advantages of using SAE 12L14 Bright Bar in precision engineering applications?

A: Its high machinability and free-cutting properties greatly reduce tool wear and machining time, leading to cost-effective production and finer surface finishes, making it highly beneficial for manufacturing intricate components such as shafts, bushings, and fasteners.Q: When should SAE 12L14 Bright Bar be chosen over other steel grades?

A: This grade is ideal when projects demand excellent machinability and smooth finishes, especially in the mass production of precision components where efficiency and surface quality are critical. Its typically selected for applications in the automotive, engineering, and fastener industries.Q: Where can SAE 12L14 Bright Bar be sourced or supplied?

A: It is widely available through various supply channels, including dealers, exporters, importers, manufacturers, wholesalers, retailers, and traders globally. Its compliance with recognized standards ensures availability for both domestic and international markets.Q: What processing methods are applied to achieve the bright finish and dimensional tolerance?

A: SAE 12L14 Bright Bars undergo cold drawing, peeling, or turning followed by polishing. These processes enhance both dimensional accuracy and surface smoothness, meeting strict tolerance requirements such as h9 or h11.Q: How does the chemical composition of SAE 12L14 contribute to its free-cutting properties?

A: The carefully controlled levels of sulfur and lead in the alloy significantly improve chip breaking and machinability, making it easier and faster to machine than standard steels while maintaining adequate strength and purity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN1A Steel Category

28mm EN1A Cold Bright bars

Alloy : Low Carbon Free Cutting Steel

Material : EN1A

Strength : Tensile Strength 370470 MPa

Chemical Composition : Carbon: 0.15% max, Manganese: 0.801.00%, Sulphur: 0.270.35%, Phosphorus: 0.07% max

Color : Silver Grey

Moisture : Nil

EN1A Leaded Bright B

Alloy : Free Cutting Steel (EN1A Leaded)

Material : EN1A Leaded Mild Steel

Strength : 400550 MPa (Tensile)

Chemical Composition : C: 0.15% max, Mn: 0.80% max, S: 0.25% 0.35%, Pb: 0.15% 0.35%

Color : Bright Silver

Moisture : Nil

Sae 1213 Bright Bars

Alloy : Low Carbon Steel (Sae 1213)

Material : Steel

Strength : Tensile Strength 440 MPa (min)

Chemical Composition : C: 0.13%, Mn: 0.85%, P: 0.040%, S: 0.045%

Color : Bright Silver

Moisture : Nil

EN1A Bright Bars

Alloy : NonAlloy

Material : EN1A

Strength : Moderate tensile strength

Chemical Composition : Carbon (C): 0.09% 0.13%

Color : Silver, Bright

Moisture : Low moisture content

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS