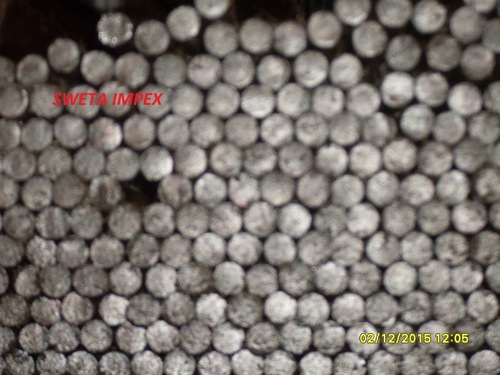

Mild Steel Sheets

Mild Steel Sheets Specification

- Purity

- 98% - 99%

- Strength

- Tensile Strength 370 - 470 MPa

- Hardness

- Brinell Hardness 120-180 HB

- Product Type

- Steel Sheet

- Material

- Mild Steel

- Alloy

- Non-Alloy

- Shape

- Rectangular

- Moisture

- Nil

- Chemical Composition

- C, Mn, Si, S, P, Fe as per IS 2062/MS standard

- Application

- Construction, Fabrication, Engineering, Automobile, Industrial Usage

- Dimension (L*W*H)

- Custom Sizes (commonly 1220mm x 2440mm x 1-50mm)

- Color

- Grey

- Edge Type

- Mill Edge / Sheared Edge

- Elongation

- 20% - 26%

- Thickness Range

- 1 mm 50 mm

- Packaging Type

- Bundle Packing / Loose / Customized

- Weldability

- Excellent

- Standard

- IS 2062, ASTM A36, EN10025

- Corrosion Resistance

- Moderate, can be enhanced with coatings

- Finish

- Plain / Coated / Oiled

- Density

- ~7.85 g/cm

- Surface Treatment

- Hot Rolled / Cold Rolled / Galvanized (as per order)

Mild Steel Sheets Trade Information

- Main Export Market(s)

- Western Europe, Africa, Central America, Eastern Europe, Australia, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Mild Steel Sheets

Mild Steel Sheets- We will Give YOU Mild Steel Sheets of Good Quality. The Mild Steel Sheets manufactured by us are from raw material of Mukand Ltd , Usha Martin Ltd, Neco Jaiswal Ltd.

- we will Supply Mild Steel Sheets as per your required size and quantity.

- The BEST & lowest rate for Mild Steel Sheets will be given to You

- Buy Mild Steel Sheets from us.

- we can SEE Long term HEALTHY relationship with YOU

- Please mail us Your requirement so that we can Give You our Best & Lowest quote for Mild Steel Sheets

- YES Bright Bar Manufacturer

Bright Bar Supplier

- Trusted Steel Suppliers In Mumbai

- Bright Bars We will Give YOU Quality Round & Hexagon Bright bars in EN 8 , EN 19, EN1A, EN 24, EN 31, SAE 8620, 16MnCr5 & 20MnCr5 Steel

- We Will Give Excise Cen Vat Credit EN 15 Bright Bars Bright Bar Manufacturer in India Manufacturer Of Bright Bars flat bright bars

- Quality Material Supplier

- Genuine Steel Supplier In India

- We Export Bright Bars Free Cutting Steel Cold Drawn Bright Bars Manufacturers and Exporters

- We Give Export Quality Bright Bars Chemical Composition of Alloy Steel Export Quality Bright Steel Bars Export Quality Machined Components Exporters Of Steel Bright Rods S S 304 Flat Manufacturers and Exporters

Cold Drawn Steel Exporter

Cold Drawn Bright Steel Manufacturers And Exporters Peeled Bright Round

Manufacturers And Exporters S S 316 Stainless Steel Cold Drawn Bright Rods

Manufacturers And ExportersCold Drawn Stainless Steel Manufacturers and Exporters

Peeled Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

S S Stainless Steel Cold Drawn Bright Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Steel Round Rods Manufacturers and Exporters

Carbon Steel Cold Drawn Bright Steel Rods Manufacturers and Exporters

Sae 1040 Cold Drawn Bright Bars Manufacturers and Exporters

Best Quality En 8 Bright Steel Rods Manufacturers and Exporters

En 8 Bright Steel Cold Drawn Round And Hexagon Rods Manufacturers and Exporters

Best Quality Free Cutting Steel Cold Drawn Bright Rods Manufacturers and Exporters

En 8 Steel Cold Drawn Bright Bars Manufacturers and Exporters Bright Bars

Free Cutting Steel En 8 Carbon Steel Manufacturers and Exporters Carbon Steel Free Cutting Steel

En 8 Bright Bars Carbon Steel Bright Bars EN1a Bright Bars En 8 Bright Bars Manufactures Exporters

Sae 1045 Bright Bars Manufacturers Exporters Carbon Steel Bright bars Manufacturers & Exporters

Carbon Steel Cold Drawn Bright Round Manufacturers and Exporters

Sae 1541 Steel Cold Drawn Bright Round Manufacturers and Exporters

Premium Strength and Durability

Mild Steel Sheets are crafted to provide robust tensile strength (370470 MPa) alongside optimal hardness (120180 HB), making them ideal for demanding applications. Their reliable mechanical properties and high purity (98%99%) ensure both longevity and consistent performance, even in challenging environments. These sheets are engineered to facilitate fabrication while resisting deformation under load, supporting a wide range of structural and industrial purposes.

Tailored Surface Treatments and Finishes

Customers can choose from hot rolled, cold rolled, or galvanized sheets to suit specific environmental and usage requirements. Optionally, sheets can be supplied plain, coated, or oiled to enhance corrosion resistance and longevity. Each treatment offers unique benefits, such as improved appearance, surface smoothness, or added durability, making it easier to match sheet properties to project needs.

Flexible Sizing and Edge Options

With customizable dimensions and edge typesincluding mill edge and sheared edgethe sheets cater to diverse customer specifications. Standard size options like 1220mm x 2440mm are readily available, while bespoke sizing can be arranged as required. These options simplify material integration into complex structures, reducing onsite modifications and ensuring an efficient workflow.

FAQs of Mild Steel Sheets:

Q: How are mild steel sheets with these specifications commonly used?

A: Mild steel sheets meeting IS 2062, ASTM A36, and EN10025 standards are widely used in construction, fabrication, engineering projects, automotive panels, and general industrial applications. Their excellent weldability and customizable properties make them suitable for both structural and non-structural uses.Q: What is the process for ordering sheets with custom thickness, size, and surface finish?

A: To order custom sheets, clients specify their desired thickness (1 mm50 mm), dimensions, surface treatment (hot rolled, cold rolled, galvanized), finish (plain, coated, oiled), and edge type. These requirements are reviewed, and sheets are manufactured or sourced accordingly, ensuring precise fulfillment.Q: When should I choose galvanized mild steel sheets over plain or oiled finishes?

A: Galvanized sheets are preferred when enhanced corrosion resistance is needed, such as in outdoor or humid environments. The zinc coating protects against rust, extending the lifespan of the steel. For applications less exposed to moisture, plain or oiled finishes may suffice.Q: Where can these mild steel sheets be applied for maximum benefit?

A: These sheets excel in settings that demand reliable strength, easy workability, and adaptabilitysuch as building frameworks, machinery, automobile parts, industrial enclosures, and welded structures. Their balance of mechanical performance and customizability delivers value in diverse sectors.Q: What are the benefits of choosing sheets with mill edge versus sheared edge?

A: Mill edge sheets are supplied with natural, rolled edges, providing cost-efficiency and suitability for further processing. Sheared edge sheets, cut precisely to size, ensure uniformity and smoothness, making them ideal for visible or critical applications where aesthetics or precision are important.Q: How does the moderate corrosion resistance of these sheets get enhanced?

A: Corrosion resistance can be improved through galvanization, application of coatings, or oiling. These protective treatments create barriers, reducing oxidation and prolonging the sheets durability, especially in corrosive or moisture-prone environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Round Bars & Plates Category

Tipper body Rock Breakers

Price 98.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material : high quality

Color : Grey

Alloy : no

Purity : 99

Mild Steel Plates

Price 42 INR

Minimum Order Quantity : 1 Ton

Material : Mild Steel

Color : Grey / Metallic

Alloy : NonAlloy / Plain Mild Steel

Purity : 99% (Approx)

Hot Rolled Round Bars

Material : Mild Steel / Carbon Steel / Alloy Steel (as per specification)

Color : Metallic grey with oxidized mill scale finish

Alloy : Available as both carbon steel and alloy steel

Purity : 99% minimum (varies by grade)

Office:

116, Gokul Arcade'A', Swami Nityanand Marg, Off Shubash Road, Near Garware, Vile Parle (East), Mumbai - 400057, Maharashtra, India.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free